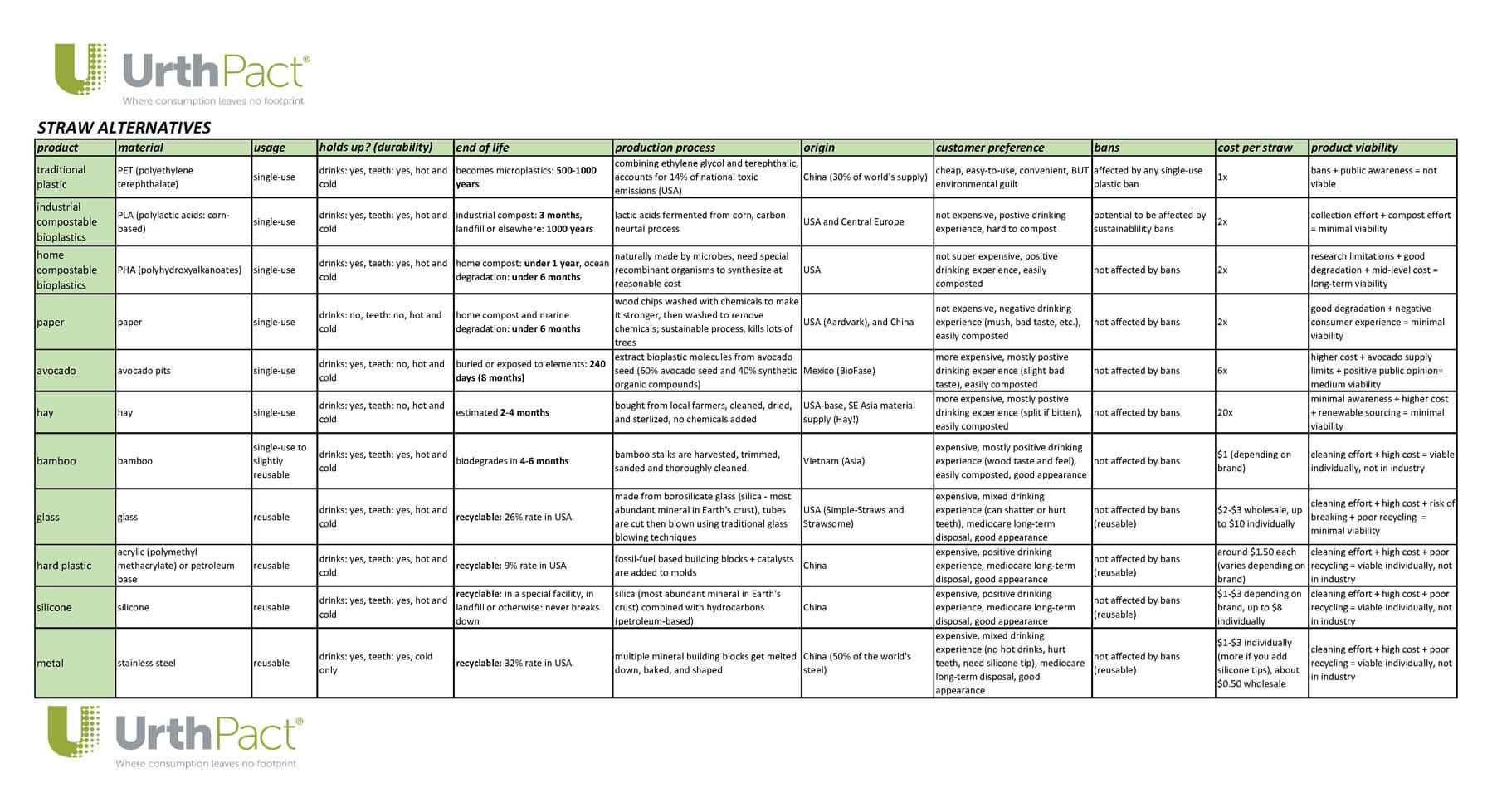

As plastic pollution on our planet continues to spread and worsen, a variety of organizations have taken steps to reduce the amount of plastic used in their products. Companies like Nestle and Coca-Cola have committed to reducing the amount of plastic used in their bottles, as well as to use more recycled-content materials in their packaging. Recyling was a good plan to start with, but we cannot rely solely on the recycling industry to handle plastic pollution. We need a long-term, widespread solution. Plastics cannot be recycled an infinite number of times, so we need to consider what happens at the end of the material’s life. A new class of bio-materials have been introduced in the bioplastics industry in the past 10 years: compostable bioplastics. These materials provide the same necessary characteristics of traditional plastics, but will biodegrade and compost at the end of their life. There are a wide range of compostable bioplastics, mainly divided into two classes: industrially (or commercially) compostable, and home compostable.

INDUSTRIALLY (COMMERCIALLY) COMPOSTABLE

A product that is labeled as industrially or commercially compostable requires increased temperatures and specifically formulated microbial conditions in order to be converted into useful compost. This is where materials like PLA (polylactic acids) fall. Made from a corn-starch or sugar-cane base, these materials retain many of the necessary characteristics of traditional petroleum-based plastics, but can be composted at the end of their lives. In the proper facility and under the right conditions, this process can occur in as little as 180 days.

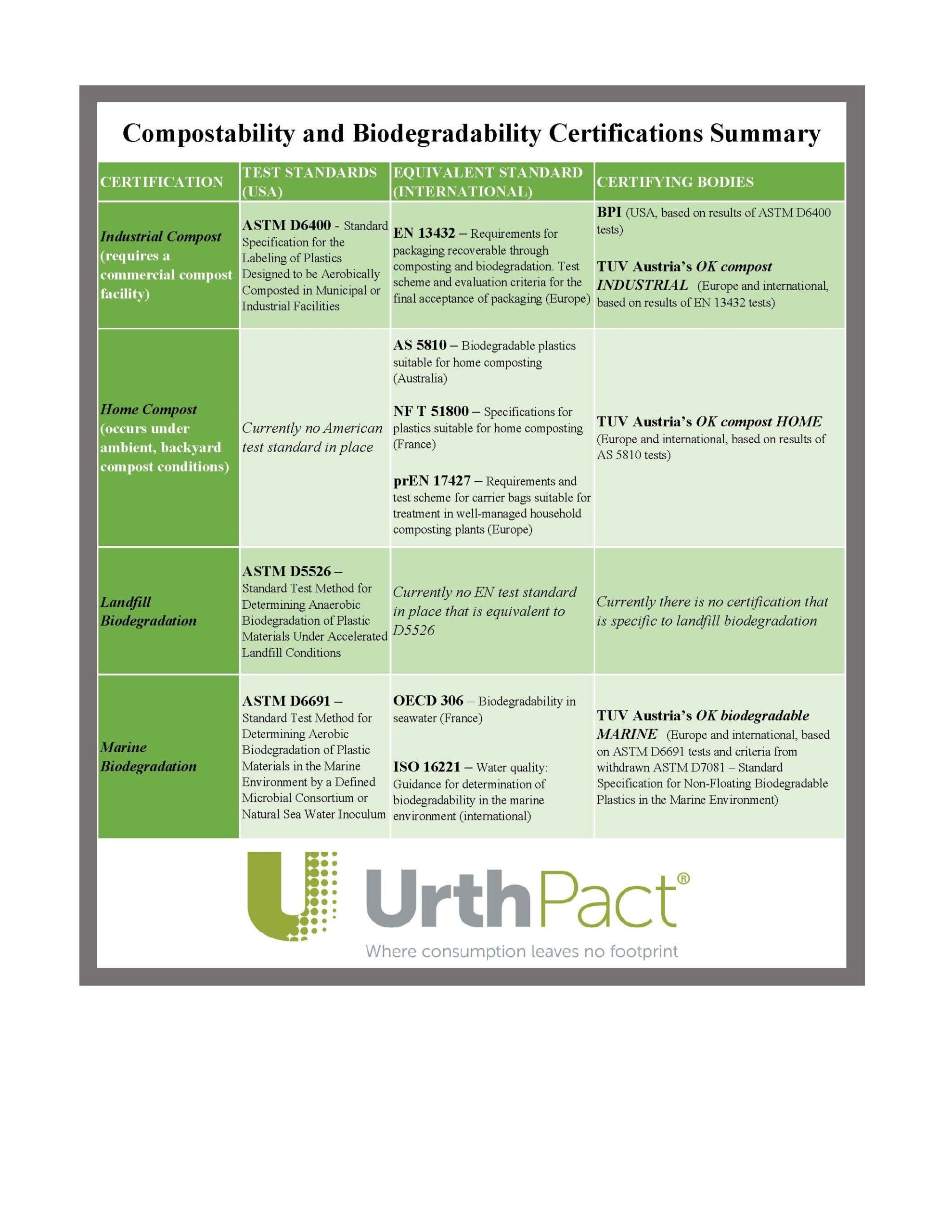

In order to be labeled as “industrially compostable” or “commercially compostable,” there are certain tests and certifications that products must pass. In the US, commercially compostable products are tested via ASTM D6400 protocols and criteria. ASTM is the American Society for Testing and Materials. Standard D6400 is the Standard Specification for the Labeling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities. This standard provides a timeframe in which both disintegration (physical breakdown) and biodegradation/compost production (chemical breakdown) must occur: 180 days. And it also requires that, in the end, the final product is of no harm to the surrounding ecosystem (ie: is non-toxic). The equivalent standard in Europe and other parts of the world is EN 13432, which requires the same timelines and results.

Once a product passes testing, the results can be sent to a 3rd-party organization for certification. There are a variety of 3rd-party certifiers worldwide. In the US, the most well known is the Biodegradable Products Institute, or BPI. In Europe, the most known governing body is TUV Austria. They offer their OK compost INDUSTRIAL certification, which is the equivalent of a BPI certification in America. So, when examining a product that is industrially or commercially compostable, keep a look-out for ASTM D6400, EN 13432, BPI, and TUV Industrial logos. Products marked with these logos are certified compostable, and you can rest assured knowing that, if you dispose of them properly, they will live a completely circular lifecycle.

A key factor to address when considering industrial compost is the number of commercial compost facilities in the US. There are much fewer composting facilities than there are landfills or recycling plants. Most small and local communities don’t support a commercial composter. This is important to consider when choosing products to use and dispose of. The United States currently only has 185 full-time commercial composting facilities. So before choosing an industrially compostable product, be sure to confirm that your community has the means to properly dispose of it.

HOME COMPOSTABLE

Home compost is the next step forward from industrial compsot. Home compostable products and materials are designed to break down and compost in a home compost environment, at ambient temperatures and with a natural microbial community. This is what sets these products apart from their commercially compostable counterparts. One of the newest and yet most common home compostable bioplastics is called PHA (polyhydroxyalkanoates), and is made from a canola-oil base. When combined with other home compostable components, it also retains all of the necessary characteristics of petroleum-based plastics, while being able to compost at the end of its life.

The requirements for labeling a material as home compostable are much newer than those for industrial compost, as the need for these certifications has only come about in the past 5 years. Currently, ASTM does not provide a test standard for home compost, and BPI has not evolved to include home compostables in their certification schemes. Home compostable tests are based mainly on an Australian standard called AS 5810, entitled Biodegradable plastics suitable for home composting. This standard requires disintegration in 6 months, and biodegradation and compost formation in a year. Based on this test standard–as well as NF T 51800 from France and prEN 17427–TUV Austria provides their OK compost HOME certification. The marking signifies that a product is certified to compost in a home compost environment in under a year. Currently, there is no equivalent certification to OK compost HOME in the US, as BPI solely certifies for industrial compost. Therefore, when evaluating a compostable product choice, OK compost HOME is the best possible certification to look for.

WHAT ABOUT MARINE AND LANDFILL DEGRADATION?

The final area of certification to address is marine and landfill environments. It’s important to remember here the difference between composting (providing nutrients and fertilizer to the Earth) and biodegrading (breaking down to innocuous elements). In a marine environment, a material cannot become compost due to the liquid medium. In a landfill environment, there is no oxygen to convert innocuous elements into usable compost. Therefore, materials in these environments can have the ability to biodegrade, but not to compost.

In a landfill setting, ASTM D5526 tests for plastic materials that are suitable for anaerobic biodegradation under accelerated landfill conditions. This process not only reduces the volume of waste in landfills, but can also increase the feasibility of economic landfill-gas recovery. There currently is no equivalent to this test standard in other parts of the world. Therefore, products that indicate having passed testing for ASTM D5526 can be classified as certified landfill biodegradable.

In a marine setting, ASTM D6691 outlines the test standards for materials to be labeled as “marine degradable.” These test standards require physical breakdown in 3 months and biodegradation in 6 months. Other test standards surrounding marine biodegradability include OECD 306 from France and ISO 16221, an international standard. There currently is no certifying body for marine degradation in the US, but TUV Austria provides an OK biodegradable MARINE certification that works off of the test results of D6691. Ok biodegradable marine is based greatly off the since-withdrawn ASTM D7081, which outlined the pass-fail criteria for products tested via ASTM D6691. However, there is a key disclaimer when certifying a product as marine degradable. In order to avoid consumers simply tossing trash into the oceans because they know it will eventually safely biodegrade, the certification can only be issued to products that are meant for use in a marine environment (for example, fishing gear).

HOW TO KEEP IT ALL STRAIGHT

It’s a lot to process and keep track of. Due to past issues of greenwashing, compostable and biodegradable products have to abide by a multitude of regulations in order to communicate their environmental benefit to customers. Here’s a quick summary to help: